Have you ever wondered, why barefoot shoes are so expensive? Even though they have less “material” on them than a traditional shoe. The reason is simply that they are much more complicated to make.

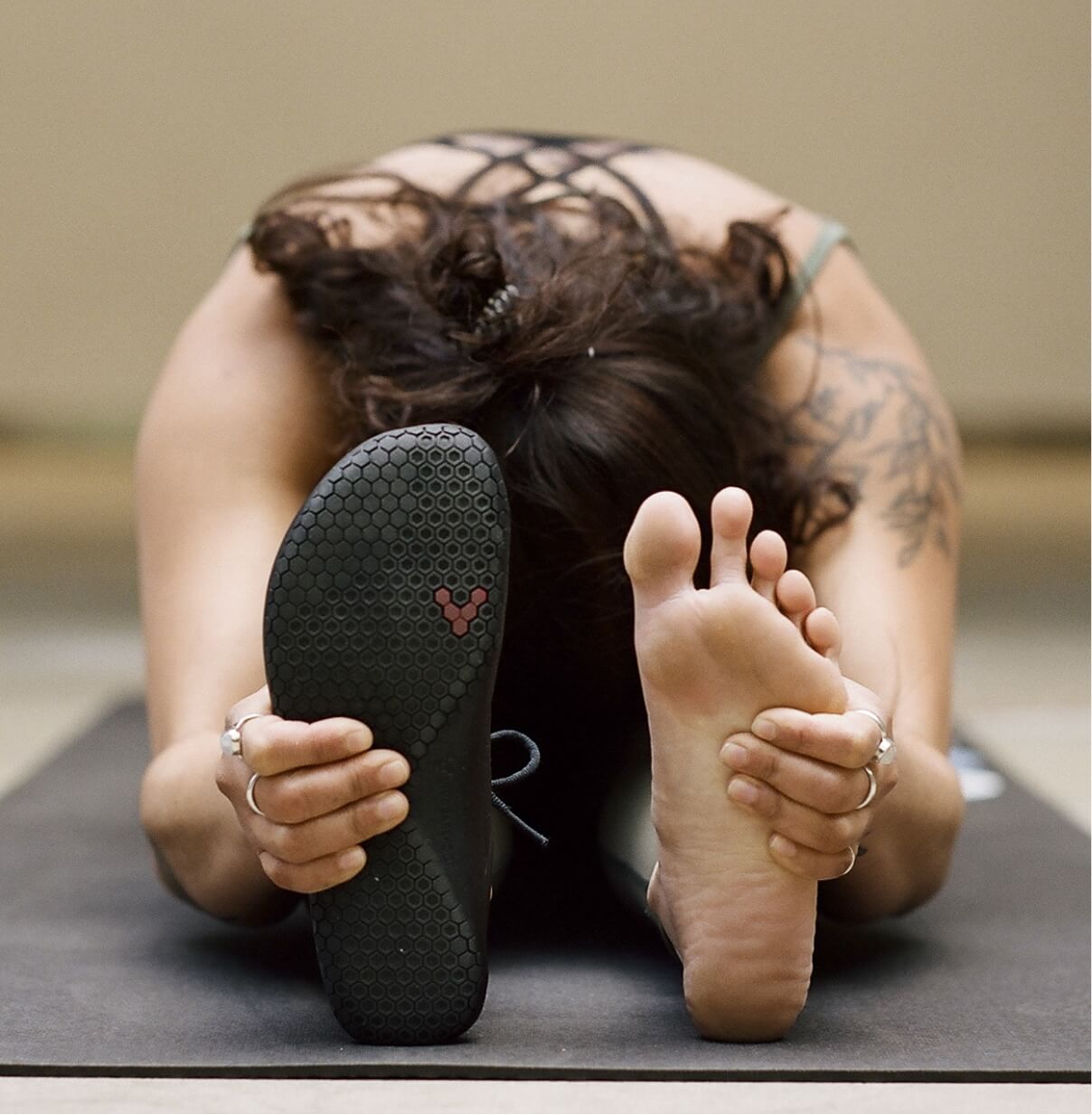

All shoes contain the basic components of upper, insole (the part that connects with your foot) and outsole (the part that connects with the ground). Conventional shoes also contain a midsole, it is the midsole that usually holds the cushioning and supportive parts of the shoe. The aim of a barefoot shoe is to make it as minimal as possible with the thinnest possible sole. Therefore, unlike conventional shoes, there is no midsole in a barefoot shoe.

To make a shoe without this midsole requires special techniques. Shoe manufacture uses a lasting machine to cement the upper to the sole of the shoe. Without a midsole it is much harder to cement the upper and outsole together. The thin insole layer can easily get wrinkled in the process leading to rejection. In some cases almost 30% of barefoot shoes are rejected due to irregularities in insole smoothness. Of course in traditional shoes these irregularities exist as well, but are more easily smoothed out by thicker and numerous layers on the mid and insole.

It can be a real nightmare for a shoe factory where production efficiency is a key-factor in profitability and therefore pricing. The problems are even more severe when we talk about children’s shoes, as everything is so small and therefore more complicated. For this reason it is much slower and more expensive to produce a barefoot shoe.

With thanks to Feelmax for providing the information

Free UK Returns

Free UK Returns